|

REMEMBER TO CLICK PICTURES FOR MORE DETAIL /

LARGER PICTURE

|

|

It looks so forlorn sitting there it is time to start working on it

again |

|

The blower needs to be bolted to the intake. We have

been using steel threaded rods for mockup, but that will not due for

running down the track. Roo Man made up some aluminum bolts which

will break if there is a problem. The threaded holes in the intake

are blind threaded holes and each is a different depth. I measured,

cut and numbered each rod for each hole to get the maximum depth and

still have as much thread in the arcon nut as possible.. I still

cannot get the show car out of my blood. |

|

|

|

|

|

Spent a little money on pulleys today. It turns out

that after these arrived, two reasons why these may not

work out came to light. One is my fault and the other is out of my control, more

on both these reasons later, read on. |

|

|

|

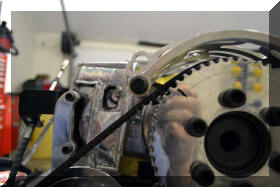

This is leading you down a

guided path to a dead end, I'll let you in on the secret in just a

minute. If yo look closely in the first picture you will note that

for some reason RCD used cap screws to hold the stand offs for the

belt guard on the two center bolts. These bolts over hang the

pulley. I am under driving the blower which means there is a large

pulley on the top and I want to be able to tune to a 8.5 index. That

means I might want to go to an even larger pulley. So.... off

came the guard, the standoffs were shortened and the cap screws were

replaced with countersunk Allan head bolts. |

|

|

|

Ok, I will now let you in on

one of the secrets why these pulleys. The current setup on the

blower drive (43 tooth lower pulley, 54 tooth upper pulley) will

give me a -20.4 percent under drive. Preliminary stabs at a tune-up

suggest that will be to fast for an 8.5 index and that a larger

pulley will need to be installed on the blower. When we were doing

the above fix the problem below came to light. Now I know you are

saying why didn't you see that earlier, in my defense at lest 15

people have been working on this and no one saw it. You had to get

down at the right angle to see it. When we turned the engine over

with the started there is just enough clearance that the belt doid

not hit. |

|

|

|

So.... I obviously cannot go

to a larger pulley to slow the dragster down to the 8.5 index. The

second shoe fell when I went to the Gasser Racing Series drivers

meeting. They handed out the new rules for the 2013 season (got a

feeling for where this is going)? The new rule inserted in the rule

package read, Supercharger Permitted but limited to standard roots

type, well I have been working on this high helix modified retro

blower since last fall. So... $3,500 later and new standard

Littlefield blower with a new spacer has been ordered. That will put

me within the rules and decrease the size of the upper pulley (kind

of like hitting a nail with a sledge hammer, but it works. Oh yes,

one more thing, I got a call from GRS officials after I place the

order , that is not what they meant by the rule, they just did not

want centrifugal blowers. My High Helix would have been ok. |

|

The engine will not fire without spark so a

bracket has been made for the coil. |

|

Another stumbling block for

firing the engine is timing so we (the car nuts) made a cylinder

stop out a spark plug and found top dead center. Anone that tells

you that breaking out the ceramic in a plug is easy has not done it.

It easy to crack the ceramic but to get it out without damaging the

rest of the plug is hard, we went through 4 plugs to do it. TDC was

one and a half degrees off a ten degree mark on the degree wheel. It

has been permanently marked on the degree wheel. |

|

|

|

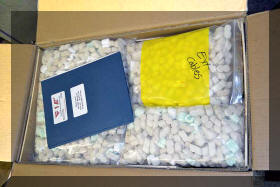

Got a present from Spud Miller today, tune up

and flowed fuel system |

|

|

|

|

|

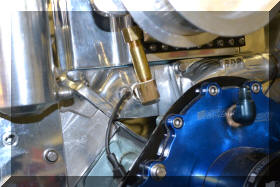

With the pump back, the final

fitment of the bracket to hold the pump could be done. the end

result was a bracket that can adjust the belt tension of the fuel

pump, and hold the cable for the fuel shut off cable. |

|

|

|

Now starts all the little

tasks that is 10% of the total task, but 90% of the time spent

fiddling. The feed line to the distribution block hits the blower

restraint. |

|

|

|

Bolted the hat on, getting close, I think this

Saturday we will try an fire it. Made a small modification to the

hat so that it is easier to bolt on. |

|

|

|

|

|

The coolant fill tank is not connected to the

pump. |

|

|

|

http://www.youtube.com/watch?v=r6zRsObuerw&feature=youtu.be |

It Runs. |