|

REMEMBER TO CLICK PICTURES FOR MORE DETAIL /

LARGER PICTURE

|

|

I am

combining the car nuts meetings of 11/3/2012 and 11/10/2012. I will

finally be caught up.

There will

be no car nuts meeting for 11/17/2012

I received

yet another injector hat in the mail, this one is a bug catcher that

came with a bunch of other parts which we will be able to use.

Packing was not great, and the items were not in as good of

condition as hoped. Fee-Bay is always a crap shoot. |

|

|

|

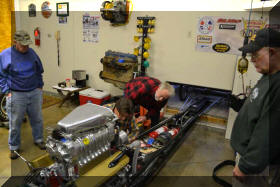

We had a number of

contributors through out these to gatherings |

|

With the addition of the

bug catcher the workbench is being taken over by injector hats and

carburetor scoops. |

|

The Enderle BarnDoor has

now been sold |

|

and the bug catcher will

be put up for sale. The alcohol carburetor will be held on to as

plan “B” |

|

Between Ray and Steve we

were able to come up with plan for the spacers needed for both the

bottom pulley and the idler pulley |

|

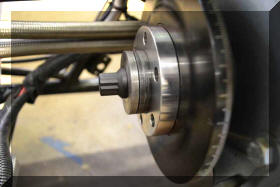

The bottom pulley was

fairly interesting as a number of things had to happen |

|

, the pulley had to be

moved ½ inch out from the hub to get the belt to ride in the center

of the pulley |

|

, by doing

this we lost the register for the fuel pump drive, also with the new

crank hub the stock retaining washer was to small in diameter to

reach the outside diameter of the new crank hub. So Ray machined a

new retaining washer that had the outside dimension of the crank

hub, The washer was stepped so that it would fit inside the crank

hub. |

|

|

|

With the

outside dimension the same as the hub and sitting proud of the hub

this became the register for the fuel pump drive. |

|

|

|

It goes together like

this |

|

|

|

|

|

|

|

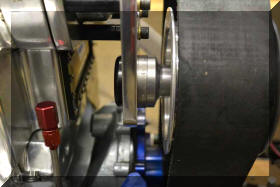

The Idler pulley was a

lot easier, all it required was a 5/16 spacer to get the belt into

the correct position |

|

|

|

I have been told a number

of times that my gold colored valve covers are not everyone’s

favorite, I happen to think that they go nicely with the gold leaf

stripping on the body of the dragster. |

|

An informal vote was

taken amongst the car nuts and it has been decided to go to a set of

fabricated aluminum valve covers, what do you think? |

|

|

|

Oil was added to the gear

housing on the blower and the snout bolted into place, Jack did the

honors. |

|

The four

inch spacer has been machined in three areas, material was removed

from the front top of the spacer to acuminate the retro outlet of

the blower (A retro blower has it’s outlet further forward than a

standard blower which is supposed to increase the efficiency of the

blower). |

|

|

|

|

|

The front outside was

machined to accept a burst panel frame. The current BDS manifold has

a pop off valve at the rear which is not acceptable by either NHRA

or IHRA. Lenny installed the panel |

|

|

|

|

|

The bottom of the center

rib was machined out to allow for better flow inside the manifold

from front to rear |

|

In the vein of reasoning

that nothing can remain untouched the Birdcatcher injector hat will

not remain untouched. The barrel valve that was on it will be

switched to a “K” valve, by Jack and Lenny. (Please no e-mails about

the alignment of the “K” valve lever to the shutter lever on the

injector hat) |

|

|

|

The hoses that were on

the birdcatcher have been removed and new hard lines installed |

|

|

|

The oil filter lines have

been “protected” |

|

|

|

So here is the finial

fitment check |

|

|

|

The valve

covers do not fit right and will have to be modified, I wish the

belt was centered more on the upper pulley

Plans are

now moving forward to the mounting of the pump. The pump will be

remote mounted and driven by a belt from the bottom pulley. This

pump came with the stuff from Fee-Bay. It is a Hillborn 150A-0 pump

which turns out to be way too small for this application. The remote

mount however appears that it will work out with some modifications.

|

|

|

|

A new Enderle 80A-1 has

been purchased and the Hillborn remote mount will be modified to

accept the Enderle Pump. |

|

|

|

That's it for a couple of weeks, other

projects require my time. |