|

REMEMBER TO CLICK PICTURES FOR MORE DETAIL /

LARGER PICTURE

|

|

The engine is back and now to

tackle some misc task to get the engine back into the dragster.

First task is to get the engine painted. A good car nuts project. We

have been through this before so not a lot of words, just pictures.

It came out pretty nice thanks to the help of the car nuts! |

|

|

|

|

|

|

|

|

|

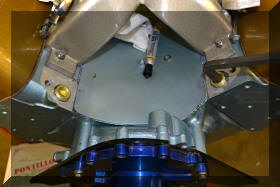

We discovered that the water

cross over was contacting the valley pan. This is the second valley

pan that I have purchased that has not fitt well, first one was from

Butler, and this one is from BPO Engineering. By pressing on the

upper half of the manifold that bolts to the head the other side

would rise up, pivoting on the edge of the valley pan |

|

|

|

Note the gap between the head and the water

crossover. We found an easy fix, We ground off some material from

the under side of the crossover See the pictures below for the

indicator mark on the bottom of the crossover and the area that we

ground out |

|

|

|

It now sits flat against both heads and the

holes are lined up. |

|

Now on to a larger task. We

have been pledged with a close to over heating problem. I can drive

to the staging lanes, make the run, drive back to the pit and be at

180 to 200. There have been may proposed fixes for the problem. We

decided to go with restricting water from the front two ports on the

heads, and pulling water from the rear ports. The rear ports are

normally plugged. There is an adapter made to allow you to do this

and it bolts onto the stock filler neck. We drilled and taped the

back side of the water crossover. I have this adapter, but it would

have required us to run the rear water return lines on the outside

of the intake. So.... |

|

This is the water crossover with AN fittings

installed on the back side. Below you

see the plugs removed from the head, 3/4 to 1/2 brass pipe reducers

and 90 degree 1/2 inch to AN fittings installed |

|

|

|

As I stated above I want to

restrict the front ports to the same size as the rear ports so the

pump pulls equally from both the front and rear ports on the heads.

I bought brass hex head female plugs, cut them off even with the

heads and drilled 1/2 in holes in them (equal to the holes in the AN

fittings in the rear. We cut slots in them so I can use a large

screw diver to both install and remove them. |

|

|

|

|

|

Now the "hard" part. I could

run braided line between the fittings, and I thought about doing

that, as I was worried about expansion of an aluminum hard line

between the fittings, but it was pointed out to me that the heads

are also aluminum and should expand at the same rate. So we made up

aluminum hard lines that fit exactly between the fittings. |

|

|

|

|

|

All lines are finger tight, no stress on any

of them or the crossover and the bolt holes for the crossover are

centered on the threads for the bolts in the heads. |

|

|

|

|

|

|

|

|

|

|