|

REMEMBER TO CLICK PICTURES FOR MORE DETAIL /

LARGER PICTURE

|

|

It has been

awhile since I produced an update. I'm skipping around but will go

back and fill in the gaps so keep checking the site for past and

future updates. |

|

Ok, had a

great turnout today and it was very productive. A lot of the tasks

on the board were crossed off. |

|

Lenny and his grandson (I cannot remember his

name, shame on me) bled the drakes one last time. |

|

Bill crated a bushing to go around the

transmission coolant lines where they pass through the chassis. |

|

Steve installed the drive shaft. The engine

was started, the transmission was run through its gears, the

transmission brake was tested, and reverse was tested (this

transmission has a pro brake in it so you have to hold the

transmission brake in order to get reverse). All worked correctly. |

|

|

|

|

|

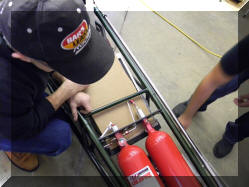

The fire

bottles were removed by Steve, Lenny and Lenny's grandson for the

trip to Indiana as they are not allowed to freeze (garage is always

heated so up to this point it was ok to leave the bottles in the

chassis). All the fire suspension lines were check for tightness.

|

|

|

|

Jack

added a clamp on the fuel line as it was unsupported in the upturn

to the carburetor. |

|

|

|

Tom made yet another bracket for the dragster,

this time it was to add support to the remote oil filter lines. |

|

|

|

The valves covers are back from the machine

shop were the insides were machined out to reduce their weight.

These are case covers and weighed a ton. They are taller than the

stamped covers that were used to keep the paint off the rocker arms

when the engine was painted. Tom and Vince adjusted the spark plug

wires so that the new valve covers would fit under the wires. |

|

|

|

As if

there was not enough going on we had a side project going on. That

project was to build some stanchions that will be used to rope of

the dragster at the upcoming show. Billy, Don, worked on this

project. We are build these stanchions from an interesting

collection of items. The bases are old rotors (which have been sand

blasted), the posts are 2 inch electrical conduit, The conduit is

fastened to the rotor with conduit connectors that have had their

retaining nuts welded to the rotors (they can be unscrewed from the

nut welded to the rotor), The top is a fence post cap that is fit on

top of another conduit connector that has been cut in half. The

stanchions will all be powder coated so all the pieces match. |

|

|

|

|

|

|

|

|

|

The tail

light has been installed by Vince. The plan is to light the tail

light at the show with a small power supply. |

|

|

|

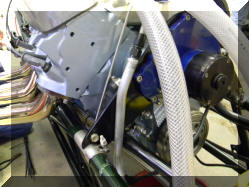

The throttle cable was move to run under the

oil pressure gauge line as it was kinking the line. Braided line has

been ordered to replace the plastic line. |

|

|

|

The valve

covers have been powder coated gold and then clear coated on top of

that. Burns down tubes have been added and the completed covers have

been bolted on the dragster. |

|

|

|

|

|

As a finishing touch for the show Lenny and

his grandson bolted on some wheel caps on the wheels. |

|

|

|

So as you

can see a lot of small tasks were completed today that have been

hanging on for dear life on the to do list, but are now complete.

The body

that is sitting on the back porch will be coming back into the

garage and be reinstalled on the dragster this week. There are a

number of tasks that need to be completed to go racing (not the

least of which is to address the overheating problem, can anyone

guess how that will be addressed? It will definitely get you

attention when you hear the solution.)

The

current plan is to load the dragster this coming Saturday, Sunday,

or Tuesday depending on weather. We will need a number of helping

hands to get it down the driveway. I know that Sunday is the super

bowl but this can be done in the morning and should not take too

long. Let me know what days you can help out and I will add that

into the mix of the weather. I did watch the extended weather

tonight and Saturday looks to be promising at the moment. |

|

|