| Below is the

process I went through to install the stacks on my truck (2007 Ford,

4X4, Extended Cab, Short bed) The process should be pretty much the

same for any truck. There will be some differences between makes

and body lengths (Crew cab, long bed Etc)

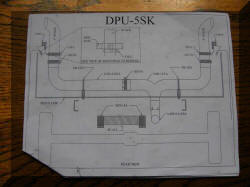

The last photo on this page is a diagram of

the exhaust system that you may find helpful.

There will be some differences between the "Kit" I got and the

"Kit" you get as I added some additional items to what comes with

the basic "Kit". Those would include the fixed length extension

pipe, the internal mufflers, the long length of flex I purchased

from the Beam Mack dealer, and the box to cover the

"Y" tube in the bed .

I had two goals: one was looks and the

second was to keep if quiet. The first was (in my opinion) a huge

success. The second still needs some work. More on that later.

The first thing I did was lay out all the parts, identify what each

of the parts were and how they went together |

|

I purchased my "Kit" form Parleys Diesel

Performance.Com. I dealt with Daniel who was very helpful and put

up with all my questions. Their phone number is 1 801 938 4891 and

their web site address is

http://www.parleysdieselperformance.com

The "Kit" is drop shipped from the vendors,

the exhaust came from Grand Rock

http://www.grpipes.com , and the "Y" tube cover box came from

MBRP. |

|

Some of the boxes unpacked. |

|

All the boxes unpacked. There was no damage to

any parts, all parts were well packed. |

|

Additional parts I ordered. The "Y" tube cover

plate for the bed, the internal mufflers for the stacks and the

extension tube to make up the difference in the length of the truck

as I have the extended cab. |

|

I also purchased from the local Beam Mack

dealer a 36 inch length of flex pipe. My reasoning for this was to

eliminate an additional connection between the extension pipe and

the supplied flex pipe (in the "Kit"). Turns out I made use of the

extension pipe, more on that later. |

|

Mandatory picture of the stacks |

1)

"The first step is to remove the exhaust from the back of the

cab all the way to the back of the truck. "

This was quite easy and the whole thing can come down in one piece.

I did jack the back of the truck up so the tail pipe extension would

come over the top of the rear axle. If you do not have a 4X4, this

may be more of a problem.

The hardest part is getting the hangers out of the rubber shock

blocks, First spray the end of the hanger stinking out of the rubber

block with silicone lubricant (don't use oil as it will attach the

rubber).

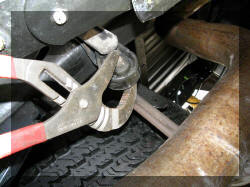

Then, I found that if you take a large pair of channel locks, put

one jaw on the back side of the rubber block and the other jaw right

on the metal hanger you can squeeze the hanger almost all the way

out of the rubber block |

|

|

|

|

|

Support the back of your catalytic converter

so it does not hang off the down tube from the engine. |

| 2)

The supplied instructions tell you to remove the heat shield from

under the bottom of the truck (if equipped). I did have a heat

shield but it was not in the way of anything so I left it inplace. |

|

3) This is the start of

the most traumatic part of the it install. "Put the long elbow into

the "Y" pipe. Place them together into the bed to determine where

the hole will go (yes, you have to drill a large hole in your bed).

A small piece of the long elbow may have to be trimmed to fit your

bed depending on the make of your truck." Mine could have been an

inch longer and needed no trimming.

MEASURE TWICE AND CUT ONCE! Take your time here!!!!!!

|

| 4)

"Figure where you want the kit located. I wanted my stacks to be

located right in the corners of the bed of the truck. This meant I

had to locate the "Y" pipe as far forward as possible in the bed,

although you have to allow for the top lip of the bed so it will not

be right up against the front of the bed. CONFIRM your hole location

from the underside and topside BEFORE DRILLING".

In my case that meant that I had to cut part

of the front cross member of the bed. I believe this is ok for

several reasons. The part that had to be cut is the upright part of

the "U" channel of the cross member. The whole front of the bed is

also part of the structure of the bed and is in the same plane as

the upright of the "U" channel of the cross member. 6 to 8 inches on

either side of this hole the cross member sits on the frame of the

truck. In addition you will no longer be able to put weight in this

section of the bed as the space is taken up by the exhaust system.

It is my opinion that this will not cause a problem. |

|

5) "After the hole is

drilled through the bed floor (there is no going back now!), place

the "Y" pipe through the hole, place the stacks into the ends of the

elbows." The hole can be created in a

number of ways. I when to Home Depot and purchased a Hole saw. If

you do this keep the speed of the saw down or you will ruin the saw.

A cut off wheel will work if you make pie cuts and then cut the ends.

If you look closely you can see the cross

member I had to cut in the hole.

|

|

|

|

Note, the left pipe can fall down as the elbow

can turn in the "Y" pipe, the right stack will stay upright by

itself. ''KEEP THE PLASTIC OVER THE

CHROME, as you do not want to scratch the Chrome while you finish

the install."

|

6)

The supplied instructions go like this:

"Hold the PUB-L and R up to the stack to determine hole

locations through the inside lip of the truck bed. The left and

right can be swapped for better and easier mounting. These

mount to the sides of the front of the bed. "

First off, I found these instructions a little confusing. What they

are talking about is the "L" shaped brackets that support the

bottoms of the stacks. I do not have a good picture of this. I got a

little ahead of myself here. I also found that I could not mount the

brackets to the side of my bed as the stake pockets are doubled

walled on my truck and I would not have been able to get to the back

side of the bolt to hold the nut in place to tighten it. I had to

mount the brackets to the front lip of the bed.

7) "Drill the holes through the bed lip and

loosely bolt the brackets to the bed."

See the pictures below. I will update these later with better

pictures.8)

"Slide the bright Accuseal Clamps over the stack and capture the

brackets with them. You can flip the clamp either way to hide the

bolt area." |

|

|

| 9)

"Slip the short 90 Degree elbow into the opening of the "Y"

(underneath). Put the flex assembly over the elbow about 2 to 2 1/2

inches." |

|

|

| I deviated a

little from the directions here. I purchased a long length of flex

from the Mack Dealer and used that rather then the short length

provided in the kit. I did this so that I would not have a second

connection in this pipe as I needed the extension pipe also, as I

have the extended cab truck. NOTE:

The ends of the flex pipe are very sharp. Be careful! |

|

|

| 10)

Instruction number 10 did not apply to me as I have an extended cab

truck. It went as follows. "Measure the length from 2 1/2 inches

into the flex forward, to go over your existing pipe that will

probably need to be cut. If you have a 3 or 3 1/2 inch diameter

exhaust pipe, reducers are available."

I did not order the reducer, and should have.

It took me a 1/2 hour to make this, if you need one buy it. I made

my own by cutting three 4 inch lengths of the extension tube,

splitting them down the middle, inserting them inside themselves,

until I had the right dimensions. Each split down the middle was

progressively smaller so that I had a tight fit. |

|

|

|

Not in the instructions. I elected to support

the back side of the catalytic converter. I purchased a standard

universal pipe hanger and attached it to a cross member that was

just in the right spot. it worked out for me. I think it makes a

stronger system and did not take much time. I would recommend it if

you are keep the catalytic converter. |

| 11)

This was another instruction that I found confusing. It went like

this. "At this point you can measure and figure where the center

clamp should go through the floor of the bed. This clamp should bolt

the "Y" pipe to the long left side elbow AND to the floor of the

bed." What they are saying is to now

use the band clamp to clamp the "Y" pipe and left side elbow together. I would leave them a little loose. The clamps that go to the

bed of the truck I found needed to be spaced up from the floor of

the bed of the truck. I found that 2 X 3 square steel tube worked

perfect. I bolted the clamp, pipe, and tube together, located the

assembly in the bed of the truck. Drilled some holes from underneath

the truck and through-bolted the tube to the truck |

|

|

| I had ordered the

internal mufflers as I wanted a quiet system. They are supposed to

be installed by placing them into the upright of the "Y" tube and

tapping into place by placing a block of wood over the top and using

a mallet tapping into place. The stack then fits over the top to

hold them in place. I found that they still rattled a little so I

then tack welded the internal muffler to the end of the stack and

then ground the weld smooth. As this end sits down into the "Y" tube

you can not see it and makes for a stronger connection. |

|

|

| 12)

"Snug up all clamps. etc. Make sure nothing is bound, rubbing, or

touching anything that it shouldn't"

Now is the time to take time to get everything straight. There is

nothing worse then a stack that is not straight up and down, and not

parallel to the other stack. I found by tacking a piece of wood and

putting over the mouths of the stacks I could line everything up and

get them straight. A couple of guys on either side and one in the

back while you make these adjustment really helps. |

|

|

| NOW DO YOU HAVE

EVERYTHING STRAIGHT?

13) "Tighten everything". 14)

"BEFORE starting the engine,

make sure the chrome is CLEAN; grease and oil free. A

hand fingerprint will "BAKE" into the finish if not clean. Start the

engine and check for leaks, etc. Retighten accordingly. Take for a

test drive and recheck."

I purchased a "Y" pipe cover and I think it

really cleans up the install |

|

|

| 15 ) ENJOY!

It was cold this morning so I took a couple of shots of the

vapor trails. |

|

|

|

|

| Ok, at this point

the installation is complete per the instructions. The pipes were

louder then what I wanted as I use the truck to haul an enclosed car

carrier. I wanted a quite exhaust system. So.... what I did was to

cut the "Y" pipe and move it over six inches so that the inlet was

between the driveshaft and the stock muffler. I then purchased

through Hearththorb Exhaust

http://www.heartthrobexhaustinc.com/

two 180 degree Mandrel bent four inch exhaust bends (1/2 in

larger then the stock 3 1/2 inch system). Those bends were cut up

and welded back together to route the exhaust from the exit of the

stock muffler to the stacks. Important, you must have a piece of

flex pipe between this set up and the stacks as the muffler want to

be able to move when the engine moves.

It is also very important that you have no

"Kinks" in you bends, they need to be smooth. The result was the

sound level was the same as the stock system which is what I was

after. |

|

|