| We

have a number of smallish projects going on so here is a

progress report on all of them |

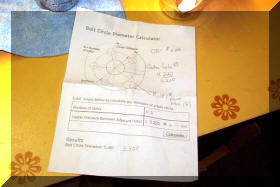

| First

up is the wheels, I have been trying to find a set of 8

inch wide original chrome wheels in good shape. I have

not been able to do that so the decision has been made

to make a modification to the aftermarket wheels I have

to try and make them look a little more original. I want

to take a set of original center caps and mount them in

the aftermarket wheels I have. The problem is how to

find and drill the holes that the screws for the center

caps so that they are in the correct location. This is

important so that the do not look like they are

wobbling as you go down the highway.

Jim has taken up the task of

creating a jig so the holes will be drilled in the

correct locations |

|

|

|

|

|

The actual drilling and mounting

should take place next weekend |

|

|

|

|

| This

Jeep will be used when we travel with the Motor Home as

a vehicle to get around in once we reach our

destination. It will be towed in a custom built trailer

which has been ordered (yes I will now have three

trailers).

The problem with this is

national parks have a limit on the vehicle size that can

be put on a camp site. The Motor Home and trailer

measure 72 feet in length. What they allow you to do

however is to park the trailer and take the MH and your

tow vehicle to the camp site and park the trailer in a

parking lot.

One method of handling this is

to make the tow vehicle capable of moving the trailer

around.

To that end we are putting the

hitch back on the Jeep, Bob and Lenny want to reinforce

the mounting points of the the hitch. I want to do this

in a way that does not modify the Jeep and it's survivor

status. The Jeep will not be used to tow the trailer

down the road, just to move it and park it in a parking

lot as it is a lot easier to maneuver that the MH.

So this is what Lenny and Bob

have come up with so far. The hitch itself will need to

be modified also. |

|

|

|

|

|

|

|

We will create a bracket similar

to this on both sides of each frame rail. The holes in

the frame exist so to put it back to original state all

that has to be done is unbolt the brackets. The bumperts

and hitch bolt though bolt through the frame and the

brackets. |

| The

gas gauge has not worked in the Jeep since I got it. As

we had to pull the tank to do the above brackets, it was

time to look into this problem.

Tom took this task on. |

|

|

|

|

It was found that the problem was

the float was full of gas and once emptied and moved

through it's range that the gauge worked.

A new sending unit and a brass

float will be put in.

The tank is in poor shape so it

will be replaced also |

|

The tanks has been painted a color

close to what a galvanized tank would look like and the

skid plate and all the brackets have been powder coated.

We should be close to putting it all back together next

weekend. |

| The

radio that came with the Jeep was an AN/FM radio. An

original AM/FM/CB radio has been installed in it's

place.

Bob has added a bracket to hold

the jack for the mike for the CB. I need a picture of

where the stock mike would have been mounted in a Jeep

that came equiped with the AM/FM/CB radio |

|

|

| When

the lift "kit" was put into the Jeep we extended the

front flex hoses but never got around to the rear on.

With the tank out now was the perfect time to finish

this project off.

Just as a note, a complete lift

is more than putting different spring in. You need to

take care of the caster change (wedges), length the flex

lines front and rear, take care of the bump steer

created because of the tie rod and drag link not being

parallel any more (tie rod flip), Lengthen the sway bar

links, check drive shaft angle, |

|

|

|

Part Two

|

|

The Car Nuts re assembled this

weekend as were the parts to be bolted on. The better

half was there to issue the marching orders |

|

|

| The

hitch was bolted up, although the brackets, bumperets,

and hitch were all mocked up before they were powder

coated it took a long time to get them bolted in place

for the finial fitting, I have no reason why other than

the project just fought us all the way. I think it

turned out well though. There are three bolts holding

the bracket to the frame and all three holes were

already in the frame so no holes were drilled in the

frame to add the brackets. I have been asked if the

hitch is original equipment, I do not know, I did find

the name Draw-Tight on the hitch. I also had to chop of

the tongue on the hitch and weld it back on pointing in

the opposite direction because the hitch hit the rear

aftermarket spring brackets, by turning the hitch around

it gave me enough clearance that no other modifications

were needed. |

|

|

|

I cannot get a good shot of the

rear brake line that was installed. The original rubber

line was too short with the lift that has been installed

on the Jeep, but now there is plenty of slack in the

line to allow articulation of the rear axle. |

|

The tank went in with not to many

problem. The decision was made not to replace any of the

vent of fuel lines as they were all in good shape and we

did not want to risk braking an plastic nibs off the

rollover valve |

|

The plastic float was replaced

with a brass one. This unit may come back to hunt me

because I pulled a real rooky mistake, read on to find

out what that was. |

|

Here we have the cleaned up skid

plate, the tank painted to look like a galvanized

original tank, the hitch, and the bumperets |

|

|

|

This is the plastic template that

was made up last week to locate the bolt holes needed

for the caps. It is not clear, but it is made out of

white plastic and is an 1/8 inch thick and worked

perfectly. We slip in a couple of studs to locate the

template and them center punched the bolt holes for the

bolts to hold the cap on. |

|

We also used the after market

center cap to take an slop out of the studs holding the

template in place. |

| I know

it is a small change for all the work but I think it was

worth it. I will continue to look for a GOOD set of

original 8 inch wide chrome wheels. |

|

|

|

|

|

|

| Ok, I

know you are all waiting for the rooky mistake to be

explained. I never checked to see if the new sending

unit worked before installing it and the tank into the

Jeep. I check the old one and it did work and played

with the idea of putting it back in, but boxed it up and

saved it. It's a Crown

part, why would I not check it before installing it. a

really stupid mistake! |

|

I only had four gallons of gas

that I could put into the tank |

|

This is how the gauge looked

before I started |

|

And this is how it looked with

four gallons in the tank. It did move but I would have

thought that it would have moved more with four gallons

in a fourteen gallon tank. I'll have to get some more

gas tomorrow and see what happens. Just shows you what

happens when you get in a hurry and don't check

everything as you go, I may end up pulling it all apart

again and putting the original sender back in |

|

Well I lucked out, I added another

nine gallons and the gauge reads about what I would

think it should. I now know that it will read empty

awhile before it actually is. Tomorrow I will top the

tank off and see it it reads full. Even if it does not

I'm happy as I now have some indication on how much fuel

is in the tank. |