| More small tasks that need

to be completed before the Jeep can be driven down the

road, First up is installing longer flexible brake lines

needed because of the lift. This left to be done is the

rear one. That looks to be changeling as the lines are

rusted up. I may have to replace some of the steel line.

First up is to remove and replace

the Power steering gear box for the third time. The

first time was because the box had so much slop in it it

was unsafe to drive. The second was because the new box

was so tight that the steering wheel would not return

after making a corner, and the third time (this time)

was because the input shaft seal was leaking (found this

when I was fixing the leak out of the transfer case). |

|

So Tom is once again over working

on pulling the steering box out. To pull it out the

radiator has to come out to get to the power steering

lines on the top of the box. |

|

|

|

So the old box is out and we have

a new pile of parts to remember where they all have to

go back. |

|

|

|

New box is here now all we have to

do is put it back and HOPE the third time is a charm. Of

course we can not leave well enough a lone, we have to

paint it up to look pretty. |

|

|

|

Now we are ready to reinstall the

gear box. Now the box is installed, ready to be primed.

Then the radiator can go back in. BUT first I want to

finish the wiring for the driving lights and do the drag

link sway. |

|

|

|

|

| Sanded

and painted the bumper, and jack. |

|

|

|

Installed the jack |

|

Installed the bumper |

|

|

| So...

now to the driving lights. There are three logical

locations (three sets of holes that can be used). One is

at the intersection of the bumper and the frame. This

set is slightly recessed back from the edge of the

bumper. The other two sets are on the bumper below the

fender, one set further out from the center than the

other set. I leaning towards the outer set of holes on

the bumper as it is more centered on the bumper. The

hole at the intersection of the bumper and frame blocks

the turn signal. |

|

|

|

|

|

|

|

|

| Ok,

next project......THE DASH

If you look at the before and

after pictures below you might scratch your head and say

what is the big deal, read on. The dash really is a

bunch of other projects.

Install a Clock and a Tech that

were never installed on this Jeep but were an option

from the factory

Replace the Speedometer

Replace the AM/FM radio as the left channel does not

work and the tuning knob is broken off

Replace all the heater control cables. |

|

|

|

First dash project

project install a Tech and Clock on a dash that never

had them. There has been

a great deal of discussion on where the Clock and Tech

should be placed on the dash.

I have receive input that says

the Clock center lines should be 7 and 1/2 inches in

from the outside edge of the dash and 5 and 3/8 inches

up from the bottom edge. The tech should be 18 or 18 and

3/8 inches in from the outside edge and 5 and 3/8 inches

up from the bottom edge. The vertical center lines

should be centered on the lights and wiper knobs and the

horizontal center line should be centered on the AIR

(heat vent control). I laid out all those lines.

I do not know if my dash is

unique in some way but all those lines ended up in the

wrong spots.

None of the 7 and 1/2 inch, or

18, or 18 3/8 inch, vertical center lines in my Jeep

line up with the center of the wiper or light control

switches. The 7 and 1/2 inch vertical center line for

the clock ended up being 1/4 inch to the outside (away

from the steering wheel) of the vertical center line of

the light switch. The 18 inch vertical center line for

the Tech ended up being 3/16 inches to the inside

(toward the steering wheel) of the vertical center line

of the wiper switch, and the The 18 and 3/8 inch

vertical center line for the Tech ended up being 3/16

inches to the outside (away from the steering wheel) of

the vertical center line of the wiper switch.

In addition to that it has been

suggested that the holes for the Clock and Tech should

be 2 and 7/8 inches in diameter.

I purchased after market

insruments (clock and tech) the bezels are the same

diameter, but the bodies have different sizes. The clock

body measures 2 and 1/2 inches where the Tech body

measures 2 and 3/4 inches.

I found that if I used the

vertical center lines from the control knobs that the

instrument bezels would have touched the steering column

bezel.

If I drilled a 2 and 3/4 inch

hole for the clock on the 7 and 1/2 inch by 5 and 3/8

inch center lines the hole would have hit the right

upper edge of the left speaker in the dash.

So......

What I did was drill a 2 and

1/2 inch hole at 7 and 1/2 inches in and 5 and 3/8

inches up for the clock.

Using the gape between the

clock bezel and steering wheel bezel as a guide I found

that drilling a 2 and 3/4 inch hole 18 and 3/16 inches

in and 5 and 3/8 inches up gave me a even gape between

the clock and steering wheel bezel and the tach and the

steering wheel bezel.

Having done all that, an tried

to carefully measure everything I did not win. It turns

out that the 5 and 3/8 inch measurement from the bottom

of the dash does not put the instruments as high on the

dash as they should be (I say that based on pictures of

factory dashes with clocks and tech and the spacing the

tech has from the upper dash board pad retaining screw,

and that if the gauges were a little higher that the

clearances for the holes and stuff behind the dash would

not have been so tight.

|

|

So here is a picture of all the

layout lines. There are center lines at different

measurements, out side bezel circles and hole circles |

|

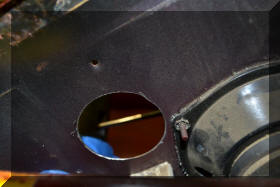

Here are the holes cut, note the

two different size holes |

|

Placement of the clock hole is

VERY important as there is a large wiring harness behind

where the clock goes and the upper right speaker mount

for the left speaker is very close to where the clock

housing will come through. This picture is the back side

of the dash to show just how close it is |

| I

created a small independent wiring harness for the tech

and clock. To have them work you need the following

feeds, ground, switched 12V unswitched 12 V, tech feed,

dash light feed. There is a spot in the fuse box for the

clock, labeled clock, for the switched feed I used the

radio feed from the fuse box as I also needed to get a

feed for the new radio to be installed. I ran a

dedicated

ground from my ground buss bar under the hood for the

whole dash, and picked up the dash light feed from the

headlight dash lable light. |

|

|

|

Here the instruments are inserted

into the holes. Note the gape between the instrument

bezels and the steering wheel bezel. Also note the

difference between the top of the Tech and the screw

hole for the dash pad screw in this picture and the

distance in the picture below. Also note that my picture

is taken from an upward angle as the steering wheel was

in the way and Keith's is taken straight on. |

|

This picture is from Keith's dash

restoration project. The entire restoration of his hash

can be seen at this link.

http://www.jeepforum.com/forum/f8/cj-dash-restoration-classic-look-1150715/index16.html#post13371355

|

|

Next up Replace the Speedometer

You have got

to be kidding me.

The

aftermarket on Jeep parts really sucks!

I ordered a

new speedometer for the jeep. The first one that came

from quadratec was packed so bad that the speedometer

was damaged in transit.

Called them

up and they promised to have one here by the weekend so

that I could install it. That did not happen.

|

|

|

|

|

| Went to

install the replacement and the back does not have a

hole for the bottom dash light, and there is an extra

hole in the upper right as you face the back of the

speedometer that lights nothing (I put a flash light to

it and it is not an indicator or instrument light). I think what

I am faced with is removing the back to the old gauge

and the new gauge, swapping the guts of the new gauge to

the old housing so that I can keep the bottom stock dash

light. |

|

Opened up the speedometer and

found that the light gels were not the same color, the

tubes for containing the brake and 4 wheel drive lights

were missing. The holes that holed the speedometer are

not in the correct position. I decided to drill the

missing hole in the aftermarket housing and transfer the

gels and tubes from the old to the new |

|

|

|

Transfer complete, lets just hope

that the new gauges work! |

|

I took lots of pictures of the back

side of the dash so that I could figure out where all the

wires were attached and then removed the old speedometer

and installed the new one. Now all the gauges and

indicator lights work except the fuel gauge. I believe I

will have to replace the sending unit in the tank |

|

|

|

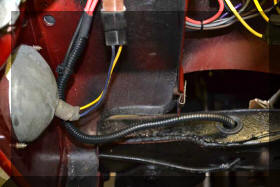

Started working on putting the front bumper back on. I

want to put driving lights on the front of the Jeep and

the Original Owner had some retro KC lights that were in

good shape. So... set up a relay to power them

(triggered by a switch on the dash and high beam head

lights). Ran the wires through existing holes in the

frame in the engine compartment (using gruments) and

drilled some new holes outside. |

| Replace the AM/FM radio as the left channel does not

work and the tuning knob is broken off

The radio I'm using to replace the

original radio is an original AM / FM Stereo / CB Jeep

radio I go off of Fee Bay. The wiring looks much more

complicated that it actually is. I did get the splitter

transformer that allows me to use the stock FM radio

antenna for the CB antenna. The speakers plugged right

up to the speaker wiring under the dash. The old radio

only had a power feed, this one has a dash light feed

and a power feed. The orange wire is for the dash

lights, brown is power |

|

|

|

|

|

|

|

I removed the old speakers and

installed new speakers purchased from Pep Boys. They are

just cheat speakers as I have no intentions of putting

an expensive system into the Jeep. If you are going to

do this be careful as the space behind the drivers side

speaker is limited because of the emergency brake pedal

bracket. The speaker cones are plastic so a little rain

will not hurt them. I intend to run topless as much as

possible |

| I

removed the connectors of the backs of the old speakers

and installed them on the new speakers so they just

plugged up to the old wiring harness |

|

|

|

New speaker is now installed. take

note of how close the speaker mount is to the new clock.

If you are drilling the hole for the clock make sure you

take this into account. |

|

|

Replace all the heater control cables. |

| So on

the surface form the first two pictures thus did not

look like much of a task, but I hope you now realize

that it was a lot of work |