|

REMEMBER TO CLICK PICTURES FOR MORE DETAIL /

LARGER PICTURE

|

|

Jim Hand's book (if you do not have this

book, buy it) For high-RPM operation, especially with solid-lifter

cams, added oil flow from enlarging the passageway from the pump to

the oil filter may improve durability. We have done this and gone

ahead and taped the hole with 1/2 inch pipe threads so that AN

fittings can be screwed directly into the block for an external oil

filter. I will be installing a System One set up. Note. when you

remove the oil filter adapter you are also removing the oil filter

bypass valve. |

|

|

|

Jim Hand goes on to say restricting oil flow

from the lifters top the rockers provides higher and more consistent

pressure for rod and main bearings. The restriction can be

accomplished by drilling, tapping and installing drilled

stainless-steel plugs into the lifter bores. A .030 inch hole in the

plugs provides adequate flow to the rockers/springs while raising

pressure for the bearings. Jeff of Kaufman Racing sells the plugs.

He recommender .046 inch hole for my solid lifter cam. Below you see

the holes tapped, the rough edges smoothed out, and the lifter hole

check for smooth operation |

|

|

|

|

|

The stroker crank wa check for clearance. Only

the right front of the block need to be addressed. |

|

|

|

Later in the install we found another issue

with the oil separator ring at the rear of the crank, and an rear

main seal issue. Those will be addressed in next weeks update. |

|

First step mock things together, and check

valve to Piston clearance. Turns out there is LOTS of room. If you

look closely you will see the depression in the clay on the tops of

the pistons made by the valves.. |

|

|

|

Cam was dialed in at one degree advance to

obtain 106 intake lobe center line.

On the

Pontiac engine that I am building I was told that I want

the intake lobe centerline of the cam to be 106 degrees after

TDC.

That was

Greek to me.

I had to

educate myself so with the help of Matt Shaft, Jeff Kaufman, and

Jim Handís Book, this is what I found and I thought someone else

might also find it interesting.

The cam card can be seen here.

This is

what I learned;

Intake opens before TDC

26 degrees

TDC to BDC

180 degrees

Intake closes after BDC

60 degrees

Total 266 degrees

divide by 2 to get centerline

with the Intake opening before

TDC 26

degrees 133 degrees

minus 26 (Intake opening before

TDC 26 degrees) as centerline

is referenced from TDC 107

degrees

If the cam is 1 degree advanced,

the camshaft is at

106 degrees centerline

|

|

A side project was the intake. The intake was

port matched, but then the walls were to thin to get a good seal

between them and the heads, so material was added to thicken the

walls back up. |

|

|

|

|

|

|

|

Work was not completed at the time of putting

this together, the finished intake will be pictured in next weeks

update. Next is to smooth out the

inside of the block |

|

|

|

|

|

|

|

Block was then thoughly cleaned, Brushes were

used to clean all orifices, as was the crank. |

|

|

|

|

|

Time to set the pistons up. |

|

|

|

|

|

Time to file fit the rings. |

|

Use a diamond wheel to trim the length of the

ring |

|

File the edges smooth |

|

|

|

Insert the ring into the cylinder, use the

tool below to square the ring in the cylinder and check the gap with

a feller gauge |

|

|

|

Looks good. |

|

Next step was oil scraper ring tension. The

expander rings sent with the pistons were standard tension rings

(high tension) As this is a strictly race engine we decided to

reduce the tension from 35 pounds per cylinder to 20. We found that

using an expander ring set for a .60 over 396 engine that we got

down to the 20 pounds per cylinder. High end race engines try for o

pounds. They use a vacuum pump mounted on the front of the engine to

create a vacuum inside the engine block to suck the oil back in

through the holes in the piston |

|

|

|

Weight the piston so that weight can be subtracted when you

test for pressure required to move the piston with a given set of

expander rings. |

|

Install the piston in the block with just the oil rings and

expander. |

|

Use you handy dandy fish scale to find the amount of pressure to

pull the piston out of the block and subtract the weight of the

piston and you have the oil ring tension. Make sure you have someone

cover the hole so that the ring does not come shooting out of the

cylinder when you reach the "breaking point. |

|

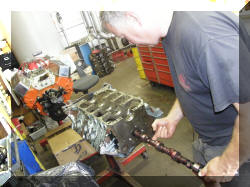

Now we can start putting stuff in for good. We

will start with the cam, which will be degreed again. |

|

|

|

|